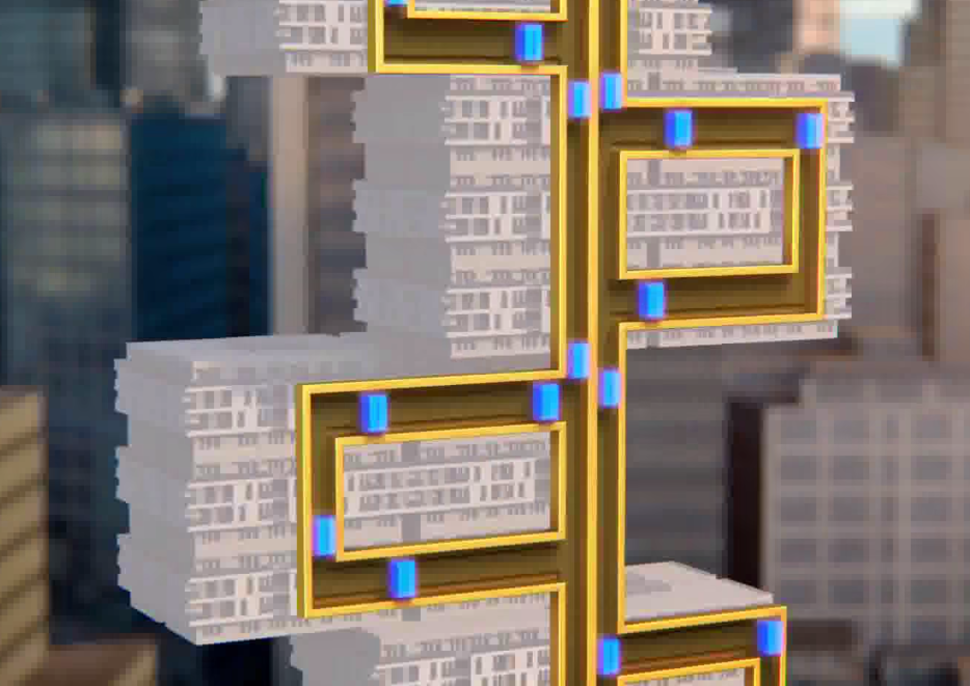

On November 5, 2015, only one year after announcing the concept of its game-changing MULTI elevator technology, ThyssenKrupp unveils a fully-functional 1:3 scale model at its Innovation Center in Gijón, Spain. The MULTI system uses linear motors instead of ropes, enabling horizontal movement and transforming conventional elevator transportation into vertical metro systems. MULTI elevator technology increases transport capacities and efficiency while reducing the elevator footprint and peak loads from the power supply in buildings.

Revealed in operation for the first time today, the MULTI system represents a landmark revolution in the elevator industry. This first scale model, with two 10 metre shafts and four cabs, applies linear motor technology based on the magnetic levitation train Transrapid. With no cables at all and multiple cabins per shaft, MULTI will transform how people move inside buildings. This latest ThyssenKrupp innovation follows the recently introduced ACCEL system, which also applies the same linear motor technology and is transforming mobility between short distances in cities and airports.

Commenting on this momentous milestone at the Innovation Center in Gijón, Spain, Andreas Schierenbeck, CEO of ThyssenKrupp Elevator said, “As we promised 12 months ago, we present today the first model of our ground-breaking MULTI elevator system. Our Research and Development team is right on track to realize this cutting-edge transport technology. MULTI will be our answer to tomorrow’s challenges: as the nature of building construction evolves, it is also necessary to adapt elevator systems to better suit the requirements of buildings and high volumes of passengers. MULTI represents a proud moment in ThyssenKrupp’s history of delivering market-leading innovations which best serve current mobility needs.”

In a manner similar to a metro system operation, the MULTI design can incorporate various self- propelled elevator cabins per shaft running in a loop, increasing the shaft transport capacity by up to 50% and making it possible to reduce the elevator footprint in buildings by half. With MULTI it will also be possible for the first time to move horizontally in a building.

Without the use of cables, MULTI runs on a multi-level brake system and inductive power which transfers from shaft to cabin. The system requires smaller shafts than conventional elevators and can increase a building’s usable area by up to 25%. This is particularly important considering current elevator-escalator footprints can occupy up to 40% of a building’s floor space, depending on the building height. The overall increase in efficiency also translates into a lower requirement for escalators and additional elevator shafts, resulting in significant construction cost savings and increased rent revenues from the greater availability of usable space.

Urbanization driving the elevator global market

Urbanization is an unstoppable trend, and the scale of movement of people to cities has redefined construction and infrastructure requirements to keep pace with growing urban populations. An estimated additional 85% of the existing urban and commercial floor space will need to be developed by 2025 to accommodate these people. Space limitations in urban areas means that mid to high-rise buildings are the most viable construction options, translating into an immense demand for elevators.

By 2020, the global demand for elevator equipment and services is projected to rise over 4% annually to 61 billion euros from the 49 billion euros verified last fiscal year.

Taking into account current construction trends of high-rise buildings, the list of the world’s tallest buildings will grow rapidly in the coming years. Currently, over 180 buildings under construction will rise above 250 meters, of which about 50 buildings will be completed every year. In the mid-rise market, there are currently about 800 buildings under construction which will rise to over 150 meters.

Developing innovations

ThyssenKrupp’s Gijon Innovation Center presents MULTI in good company. ACCEL, ThyssenKrupp’s new travellator transportation system for cities and airports, caused a stir at its launch last year, and the prototype is progressing well through its planned testing period. Behind the scenes, around 40 engineers from a wide variety of disciplines work at the Innovation Center, further developing ACCEL and MULTI, plus many other transportation solutions for the future: innovative escalators, moving walks, elevators, and passenger boarding bridges, as well as completely new approaches to safety and mobility solutions.

The Innovation Center registered 56 patents in the last six years, developing more than 55 projects and winning numerous awards. The Massachusetts Institute of Technology (MIT), one of the leading names in technology research, recently added ThyssenKrupp to its list of the “50 Smartest Companies for 2015” – in particular in recognition of its latest innovations such as ACCEL and MULTI.